3D Printing Nickel Da Alloy Inconel 718 Powder

ọja Apejuwe

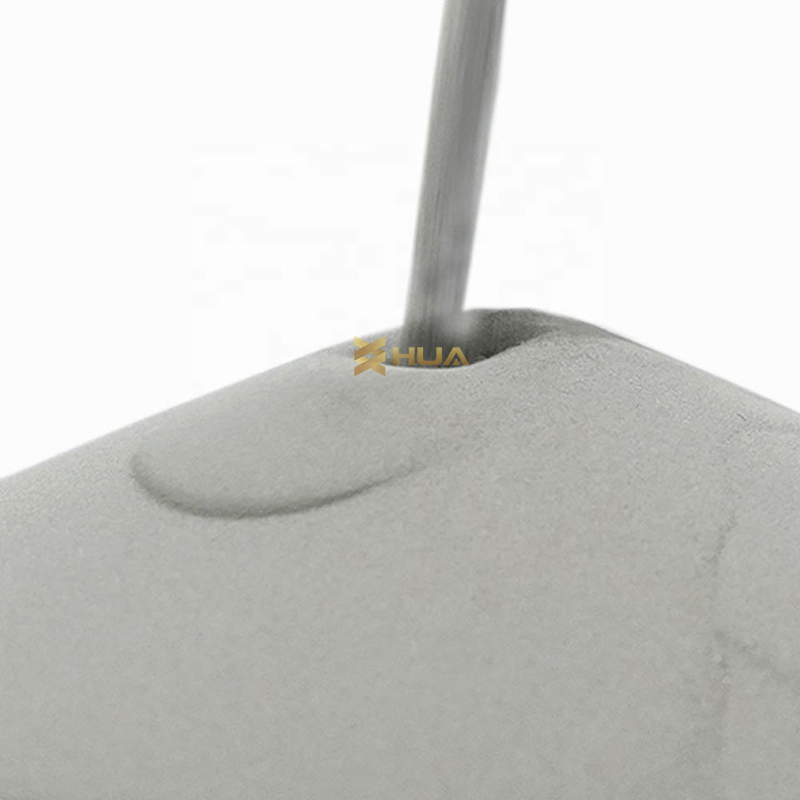

Inconel 718 lulú ni iyipo ti o dara, ṣiṣan omi, aaye yo kekere, resistance ifoyina otutu otutu, ipata ipata ati resistance resistance.Nipasẹ awọn ti o yatọ patiku iwọn pinpin.Nickel based alloy 718 lulú le ti wa ni pinpin si abẹrẹ idọti lulú, lesa cladding lulú, spraying powder, gbona isostatic titẹ lulú ati be be lo.

Sipesifikesonu

| Iṣọkan Kemikali(%) ti Inconel 718 Powder | |||||||

| C | Mn | Si | P | S | Cr | Co | Mo |

| ≤0.08 | ≤0.35 | ≤0.35 | ≤0.015 | ≤0.015 | 17-21 | ≤1.0 | 2.8-3.3 |

| Nb+Ta | Ti | Al | Fe | Cu | Ni | N | |

| 4.75-5.5 | 0.65-1.15 | 0.2-0.8 | Bal | ≤0.03 | 50-55 | ≤0.006 | |

| Inconel 718 Powder Properties | |||||

| Iwọn Iwọn | 0 ~ 25um | 0 ~ 45um | 15-45um | 45 ~ 105um | 75-180um |

| Ẹkọ nipa ẹkọ ẹkọ | Ti iyipo | Ti iyipo | Ti iyipo | Ti iyipo | Ti iyipo |

| PSD (Pinpin Iwon apakan) | D10: 6um | D10:9 | D10: 14 ọsán | D10: 53um | D10: 78um |

| D50:16 | D50: 28um | D50: 35um | D50: 69um | D50: 120um | |

| D90: 23um | D90: 39um | D90: 45um | D90: 95um | D90: 165um | |

| Agbara sisan | N/A | ≤30S | ≤28S | ≤16S | ≤18S |

| Iwuwo ti o han gbangba | 4.2g/cm3 | 4.5g/cm3 | 4.4g/cm3 | 4.5g/cm3 | 4.4g/cm3 |

| Akoonu atẹgun (wt %) | O: 0.06~0.018wt%, ASTM boṣewa: ≤0.02 wt% | ||||

| 3D titẹ sita Gas Atomized Inconel 718 Powder pẹlu idiyele ti o dara julọ | |||||

| (atẹgun kekere, agbegbe giga ati ṣiṣan ti o dara) | |||||

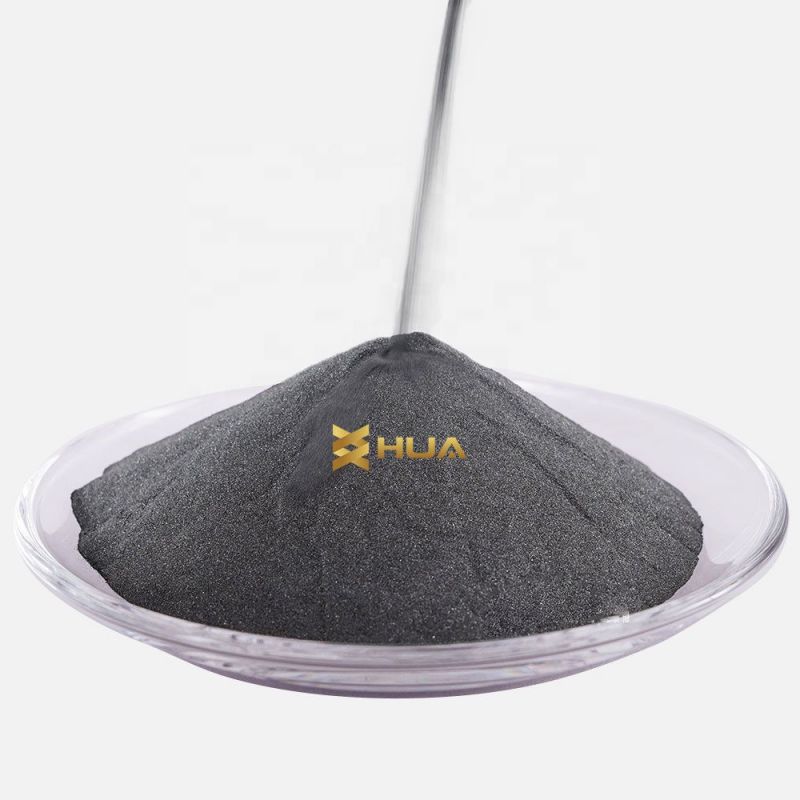

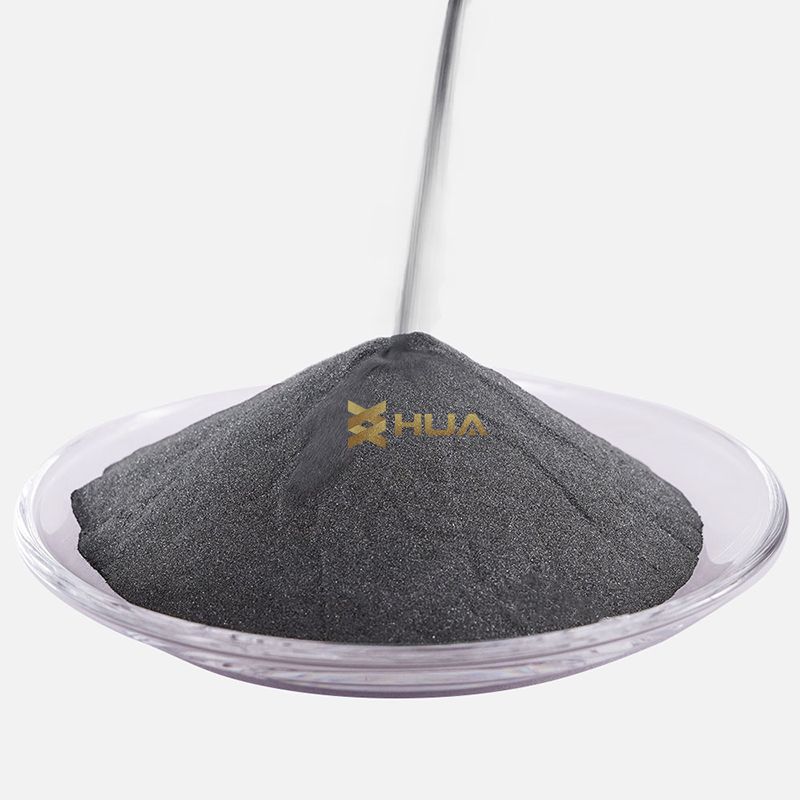

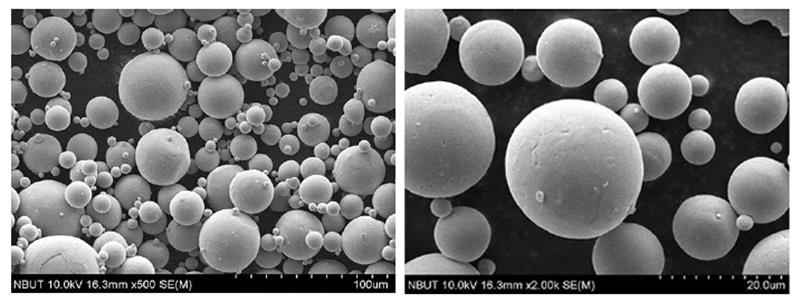

SEM

Ohun elo

1. HVOF

2. Plasma ti a bo

3. 3D titẹ sita

4. lulú alurinmorin

5. irin abẹrẹ igbáti

6. gbona isostatic

Eto iṣakoso didara

Huarui ni eto iṣakoso didara ti o muna.A ṣe idanwo awọn ọja wa ni akọkọ lẹhin ti a pari iṣelọpọ wa, ati pe a tun ṣe idanwo ṣaaju gbogbo ifijiṣẹ, paapaa apẹẹrẹ.Ati pe ti o ba nilo, a yoo fẹ lati gba ẹnikẹta lati ṣe idanwo.Nitoribẹẹ ti o ba fẹ, a le pese apẹẹrẹ fun ọ lati ṣe idanwo.

Didara ọja wa jẹ iṣeduro nipasẹ Sichuan Metallurgical Institute ati Guangzhou Institute of Metal Research.Ifowosowopo igba pipẹ pẹlu wọn le ṣafipamọ ọpọlọpọ akoko idanwo fun awọn alabara.